Product Categories

Rubber vulcanization is a chemical process at a given pressure, temperature and time for converting natural rubber into more durable materials by the addition of sulfur. These additives modify the polymer by forming cross-links (bridges) between individual polymer chains. Vulcanized materials are less sticky and have superior mechanical properties. And vulcanization autoclave is used widely for this chemical process. The main products are galoshes, rubber tubes, cable, rubber roller, rubber ball, etc.

• Steam vulcanization autoclave

• Electric heating vulcanization autoclave

• Thermal oil vulcanization autoclave

We are the leader in the fields of tyre retreading and rubber rollers vulcanization

In order to get high-quality rubber rolls, it is very necessary to directly vulcanize the rubber rolls with metal supports inside. This modified treatment is processed in SINOMAC rubber vulcanization autoclave. Inside the autoclave, the pressure, temperature and time can be controlled effectively without the help of moulds. In this field, SINOMAC has been the leader, as we have accumulated full vulcanization experience and technology for many years.

Advantages of the TPC process control software

SINOMAC vulcanization Autoclave is equipped with advanced thermal energy process control (TPC) system, which is developed by SINOMAC on the advantages of various control systems at home and abroad, is a very popular control system for customers.The system has the basic functions of user authority login, sensor selection, vulcanization process curve setting, calling, saving and printing, automatic and manual process execution, real-time data monitoring, recording, saving and printing, state monitoring of each component, alarm, quality analysis, reports and so on.

Optional PLC + HIM or PLC + PC systems

Types of SINOMAC Vulcanization Autoclave

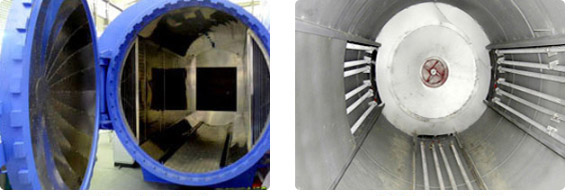

Direct heating (Steam direct Pressurizing and Heating)

This is a type of direct heating and pressurizing. On the bottom of autoclave, we set up steam diffusion tubes, where steam goes into. On the tubes, there are plenty of small holes (Ø4mm or Ø5mm) densely arranged as a regular array and tilt angle. This design can make the steam flowing inside the tubes evenly spread into space through these close-set holes. So that we can ensure internal uniformity of temperature and pressure. The temperature uniformity can be controlled within +/- 1ºC. The system heating efficiency is high, which is very important to vulcanize those heavy rubber products with big size.。

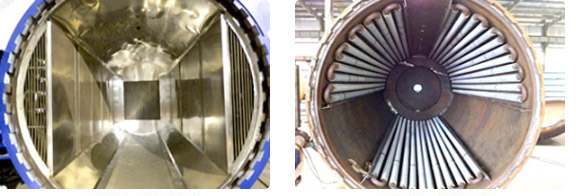

Electric Heating(Electric Heating and Compressed Air Pressurizing)

This is a main heating type. It is fast, energy conservation and convenient. For the most of rubber products required electric heating, the vulcanization process can be carried out strictly as the preset technology curve. So that user can get products of high quality.SINOMAC electric heating vulcanization autoclaves use tailor-made stainless tubular heating elements and inlay new thermal conductivity of insulating materials. The heating is fast and working life is long. All the terminals of wires connecting the heating elements are external, which can avoid the built-in wires heat to get a fire. This design improves vastly the heating system safety. By the special circulating fan and reasonable air duct design, the space inside the autoclave can obtain uniform temperature. At the same time, the pressure is controlled individually.

Indirect heating(Steam/Thermal Oil Heating and Compressed Air Pressurizing)

This type of Vulcanization Autoclaves are normally used for big metal core rubber roller and where is lack of electric power. In order to avoid the difference of thermal conductivity between metal core and rubber, normally we use a slow heating and pressurizing curve. The actual vulcanization time is much longer than the one rubber required normally. In this type of autoclave, the debonding between metal core and rubber roller will not happen.

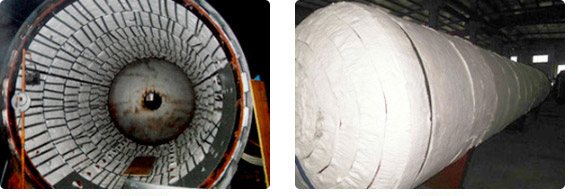

Insulation of SINOMAC Vulcanization Autoclave

Internal and External Insulation

We use ceramic fiber as the insulation material. The heat transfer coefficient is very low to make the heat loss to a minimum. The covering board of ceramic fiber is stainless steel. It is corrosion resistant and looks nice. Internal insulation design can get a low energy consumption, while external insulation design gets a high one, but a better temperature uniformity.

Hot air circulating system of SINOMAC Vulcanization Autoclave

Hot wind cycle for electric and indirect heating

The impeller uses a modified centrifugal impeller with high air volume and high wind pressure. On the dynamic seal mixing, we use the mechanical seal, silicon carbide-graphite as a static ring sealing material, to improve the service life; In wind duct design, we adopt U-type wind duct structure,There is a diversion device at the extension of the air duct, which can ensure the adequacy of the hot air circulation, make the forced convection efficiency in the kettle reach more than 90%, and ensure the rate and uniformity of the temperature rise.

高品质的部件和材料Detailed Production Process

In order to guarantee the quality of vulcanization autoclave, we manufacture the equipment under the strict process construction guidance, each working procedure, we do it carefully; for the parts, we use only the highest quality materials.

Meet the Different Size Requirements

SINOMAC can design and build the most size vulcanization autoclaves, the diameter from 0.8 meter to 4.5 meters, and the length from 1 to 30 meters.

Complete Auxiliary System

SINOMAC can offer full and complete auxiliary system, including vacuum system, pre-heating system,air-compressed system, water-steam exchange cooling device, part trolley and any other auxiliaries.

Global Service and Various Manufacture Standard

• GB150-2011

• ASME SEC VIII DIV.1 with ASME Certificate

• PED 97/23/EC with CE certificate

• AD2000

Global Turn-key Project Service

SINOMAC team has full experience and technical ability to offer global turn-key project service. You don’t have to be worried about the installation and system commissioning. We can carry out a professional and careful train for users.

Model | Inner diameter | Effective length | Usage |

SN-LHGR08 | 800 mm | 1000/1500/3000/4500 mm | Small size rubber production |

SN-LHGR10 | 1000 mm | 1000/1500/3000/4500 mm | Small size rubber production |

SN-LHGR15 | 1500 mm | 2000/4000/8000/12000 mm | Small size rubber production |

SN-LHGR20 | 2000 mm | 4000/6000/12000 mm | Middle size rubber production |

SN-LHGR25 | 2500 mm | 5000/8000/12000 mm | Middle size rubber production |

SN-LHGR28 | 2800 mm | 6000/8000/15000 mm | Middle size rubber production |

SN-LHGR30 | 3000 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR32 | 3250 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR35 | 3500 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR40 | 4000 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGR45 | 4500 mm | 6000/8000/15000 mm | Large size rubber production |

SN-LHGT1504 | 1500 mm | 1500 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1506 | 1500 mm | 2250 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1508 | 1500 mm | 3000 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1512 | 1500 mm | 3750 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT1520 | 1500 mm | 7000 mm | Truck tire repair,Middle size MAX.1300MM |

SN-LHGT2045 | 2000 mm | 4300 mm | Construction machinery tire repair,Large size Max.23.5R25 |

SN-LHGT2550 | 2500 mm | 5200 mm | Construction machinery tire repair,Large size Max.29.5R25 |

SN-LHGT2845 | 2850 mm | 4500 mm | Construction machinery tire repair,Large size Max.24R49 |

SN-LHGT3260 | 3200 mm | 6000 mm | Construction machinery tire repair,Large size Max.33R51 |

SN-LHGT4080 | 4000 mm | 8000 mm | Construction machinery tire repair,Large size Max.55/80R57 |

其他规格定制

Changzhou SINOMAC Machinery Technology Co. Ltd.

Autoclave products are exported to the United States, Canada, Russia, Australia, New Zealand, France, Brazil, Venezuela, Saudi Arabia, Tunisia and other countries.

Tel: 0086-13912342699

Tel: 0086-13912342699 E-mail: info@czsinomac.com

E-mail: info@czsinomac.com Add: No. 801 Changwu Road, Wujin High Tech Zone, Changzhou, Jiangsu, China

Add: No. 801 Changwu Road, Wujin High Tech Zone, Changzhou, Jiangsu, China