Product Categories

A polymer plastic film material (EVA PVB SGP) is sandwiched into the middle of two or more pieces of glass, and then enters the autoclave for sufficient heating and compression treatment, and the resulting glass synthesis product is called safety laminated glass. The various raw materials constituting the laminated product, especially the process of the intermediate membrane in the autoclave, are very important to obtain a high-quality product.In fact, the role of SINOMAC glass autoclave is to ensure the quality requirements of this product, its stability and production process ensure that the finished product meets and maintains high quality standards.

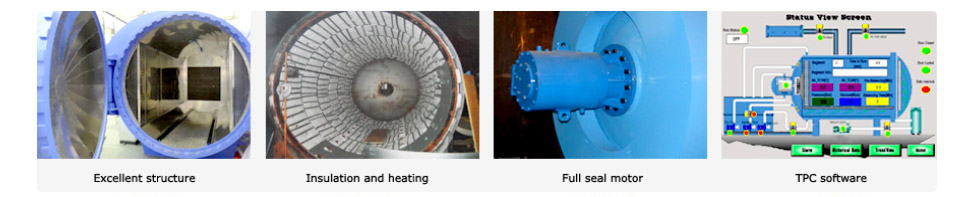

• TPC system software based on PLC control, automatic control and stability and safety

• U-shaped, annular convection structure design, ensure uniform temperature, improve yield

• Nickel chromium alloy heating element, high life, high electric heating conversion efficiency, heating power proportional output efficiency and energy saving

• Independent main cooling system and auxiliary cooling system can improve the cooling efficiency and realize the precise linear control of cooling gradient

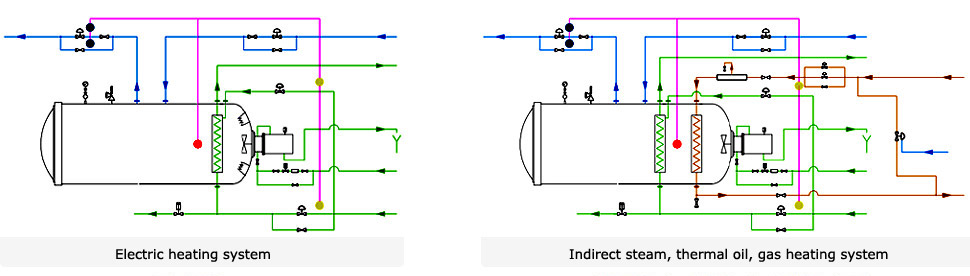

• Variety of heating systems, electric heating, steam heating or heat conduction oil heating

• With mechanical, electronic and software triple safety interlock protection function

• Suitable for safety laminated glass, automotive laminated glass, photovoltaic module packaging

Continuous innovation and improvement ensure our technology is up to date, the most important features of our glass autoclave are as below:

• Based on customer’s specific specification, we can achieve accurate temperature and pressure control in compliance with the process requirement.

• It has an on-line power consumption monitoring device, which can automatically stores the power consumption of one working process for the cost statistics and analysis.

• Optimized air duct structure, efficient circulation fan, excellent thermal insulation system and intelligent temperature control and regulation, all of these ensure uniformity of temperature and maximum energy saving.

• According to the requirements of homogenizing furnace, SINOMAC glass autoclave can also be used as preheating vacuum chamber and homogenizing furnace.

• High-quality materials and high-standard manufacturing process bring up a much safer and more stabler autoclave.

• Fully sealed special circulation fan. No leakage and no need to maintain.

• Independent main & auxiliary cooling systems can improve cooling efficiency and achieve accurate linear control of cooling gradient.

• The heating system can be electric heating, indirect steam heating and indirect thermal oil heating.

• The autoclave has mechanical, electronic and software tripartite safety interlock protection.

• The exclusively developed TPC control software based on PLC control system can realize manual, automatic or redundant operation for the working process control, and it can be connected to LAN to realize centralized management and control when entering into the factory DCS system.

• For monitoring the working process, we can choose IPC (Industrial Personal Computer), touch screen or controller as the upper monitor.

• Besides monitoring the autoclave working process, It can also monitor the auxiliary equipment system, such as gas storage tanks, air compressors, vacuum system and cooling station.

SINOMAC can design and manufacture the glass autoclave with various quick-opening modes.

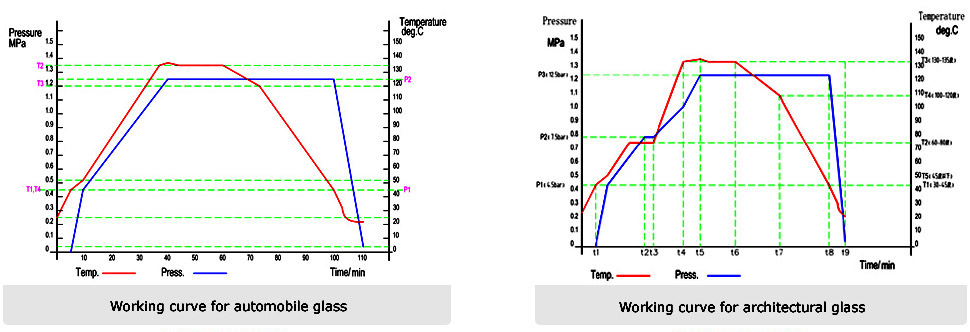

Working Process of SINOMAC Glass Autoclave

The whole operation process of SINOMAC Glass Autoclave has 9 segments. During the whole process, temperature and pressure in all segments will be monitored by HIM or PC, and the operation process will be realized by our exclusively developed TPC(Thermal Processing Control)software which is based on PLC control system to ensure the full automatic operation.

SAVE COST 30%,WE MADE THIS HAPPEN

Different Heating Mode

Our standard heating mode for glass autoclave is electrical heating. Heating element using nickel chromium alloy heater, at the same time to meet the demand of the market, we also can use other heating mode, which include indirect steam heating, thermal oil heating and gas heating.

Meet the Different Size Requirements

SINOMAC can design and build the most size glass autoclaves, the diameter from 1.5 meter to 4 meters, and the length from 1 to 21 meters.

Auxiliary Systems

No autoclave is complete without the proper auxiliary systems. The auxiliary systems we can design and provide for the glass autoclave include: vacuum system, pressurization system (compressed air and nitrogen), closed circulation cooling system, etc

Varieties of manufacturing standards to meet the needs of the global market

• GB150-2011

• ASME SEC VIII DIV.1 with ASME Certificate

• PED 97/23/EC with CE certificate

• AD2000

Turn-key Project

We can provide customers with turnkey projects for the whole laminated glass. From project planning, design, production, installation and after-sales service, SINOMAC with its very professional ability to provide users with a complete set of reasonable solutions. Customers can be assured to complete the whole laminated glass project to SINOMAC. We will complete the design and production, installation guidance, system debugging, on-site training and after-sales service according to customers' requirements with high quality and quantity.

| Model | Inner diameter | Effective length | Glass size | Design pressure | Design temp | Heating power |

SN-BGF2040 | 2000mm | 4000mm | 1700*4000mm | 1.5Mpa | 160℃ | 96KW |

SN-BGF2550 | 2500mm | 5000mm | 2200*5000mm | 1.5Mpa | 160℃ | 135KW |

SN-BGF2650 | 2650mm | 5000mm | 2350*5000mm | 1.5Mpa | 160℃ | 144KW |

SN-BGF2860 | 2850mm | 6000mm | 2500*6000mm | 1.5Mpa | 160℃ | 162KW |

SN-BGF3080 | 3000mm | 8000mm | 2700*8000mm | 1.5Mpa | 160℃ | 225KW |

SN-BGF3380 | 3350mm | 8000mm | 3000*8000mm | 1.5Mpa | 160℃ | 297KW |

SN-BGF3690 | 3650mm | 9000mm | 3300*9000mm | 1.5Mpa | 160℃ | 352KW |

Other specifications customization

Changzhou SINOMAC Machinery Technology Co. Ltd.

Autoclave products are exported to the United States, Canada, Russia, Australia, New Zealand, France, Brazil, Venezuela, Saudi Arabia, Tunisia and other countries.

Tel: 0086-13912342699

Tel: 0086-13912342699 E-mail: info@czsinomac.com

E-mail: info@czsinomac.com Add: No. 801 Changwu Road, Wujin High Tech Zone, Changzhou, Jiangsu, China

Add: No. 801 Changwu Road, Wujin High Tech Zone, Changzhou, Jiangsu, China